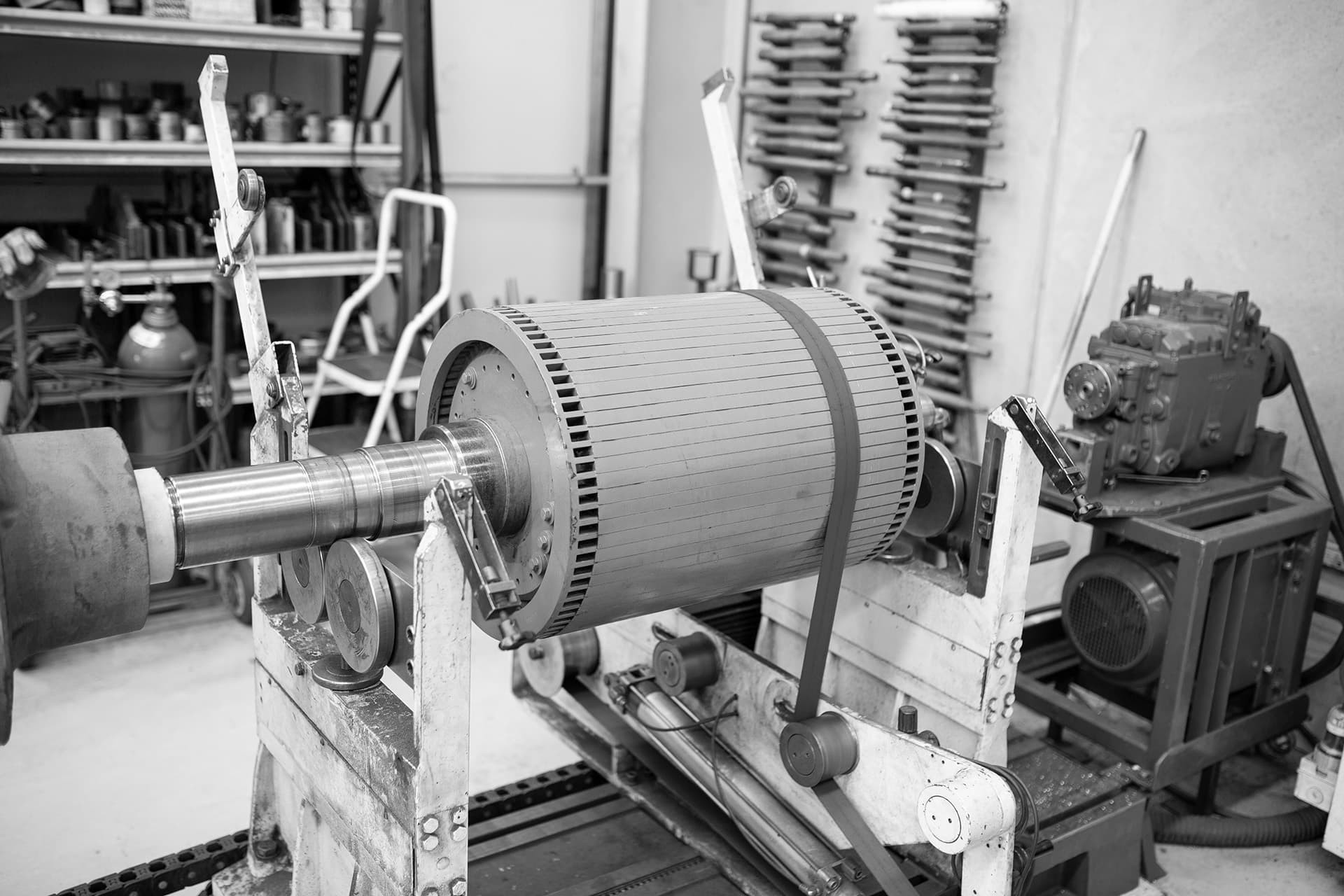

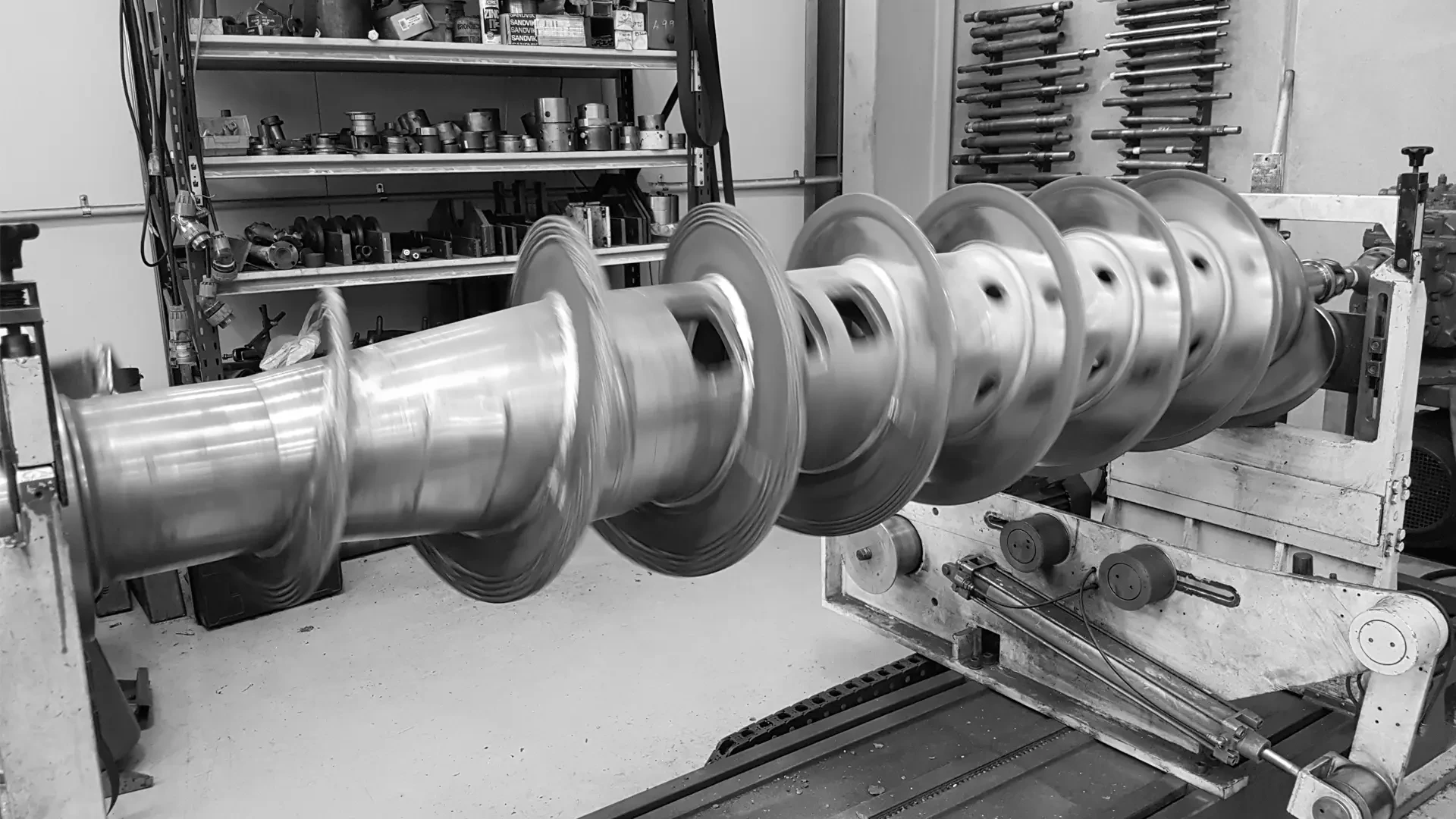

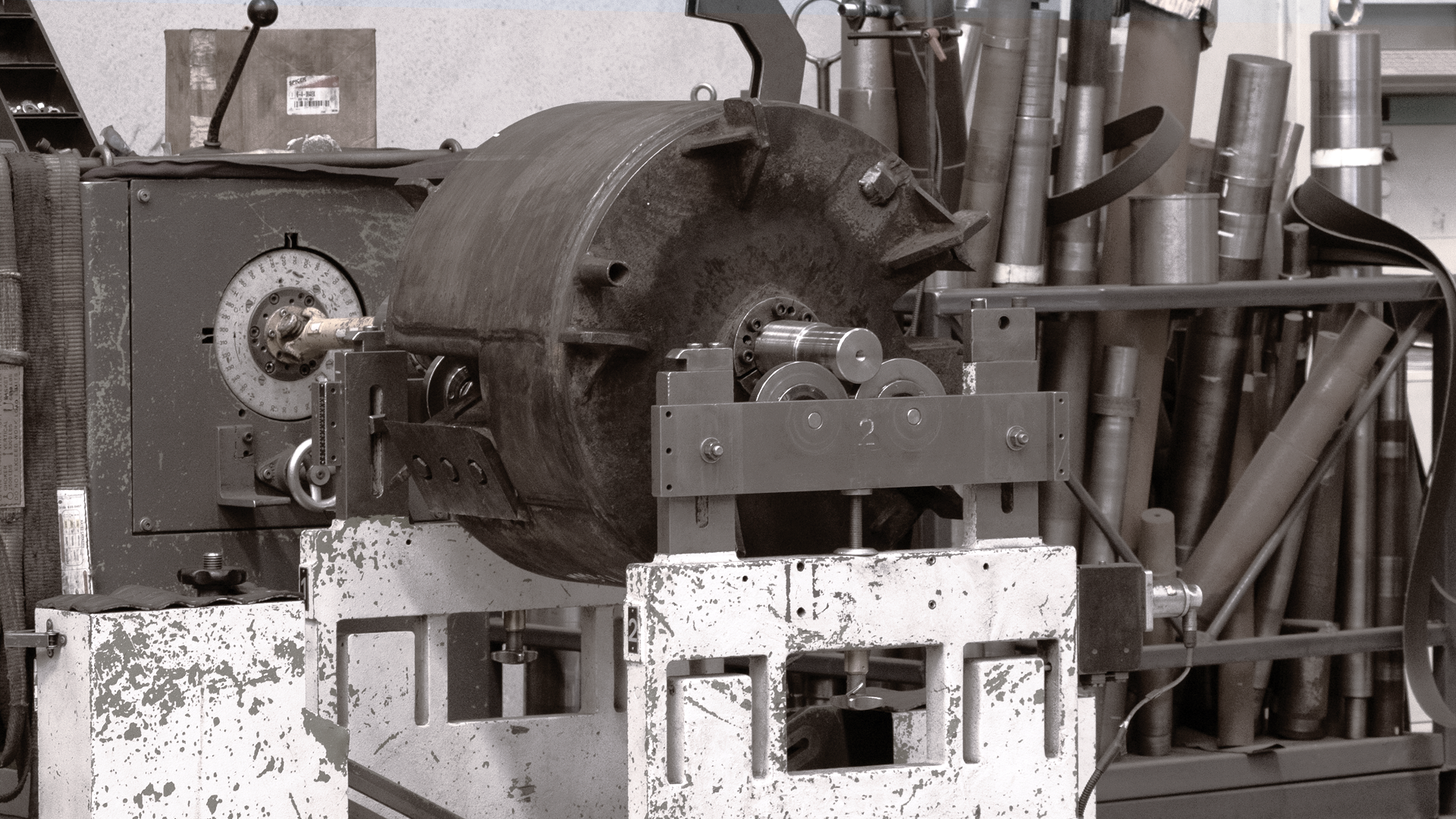

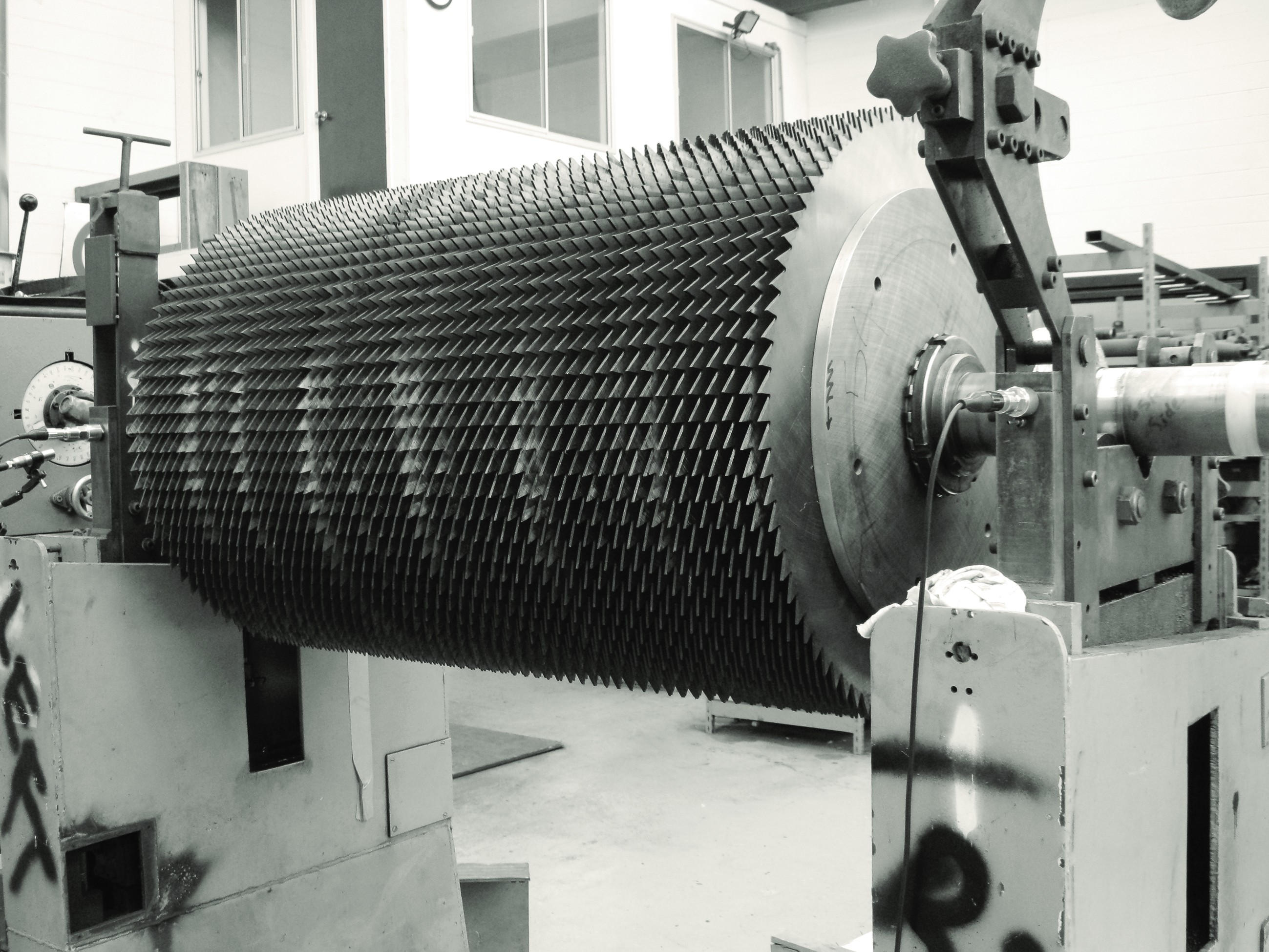

Beattys has assisted manufacturing plants across New Zealand for many years with the dynamic balancing of industrial rotating equipment.

With machines capable of handling components over 4 metres in length, 10 tonnes in weight, and up to 4.5 metres in diameter, we’ve balanced a

wide variety of items. These include centrifuge scrolls and bowls for dewatering and olive oil production, rollers for sanding and

conveying, compressor screws for gas and vacuum systems, drums for drying, separators for honey, sifters for powders, and eddy current

rollers for metal separation. By working closely with our clients, we provide a service that keeps production flowing.

- Rollers

- Scrolls / Augers

- Centrifuges

- Turbochargers

- Sanding rollers

- Seperators

- Rubber Rollers

- Compressor Screws

- Vacuum Screws

- Food Processing Drums

- Sifters

Our Process

-

ASSESS

Beattys will scope the project, identifying any critical parameters and challenges that we need to overcome to ensure we deliver a premium service.

-

ANALYSE

Our balancing technicians will attend the onsite project, complete all compliance procedures and further discuss the issues to ensure we fully comprehend the impact of vibration present.

-

DELIVER

Throughout our Industrial Balancing process, you can be guaranteed of the highest level of engineering and commitment to quality.

-

REVIEW

After dynamic balancing the rotational equipment undergoes a rigorous inspection and quality control measures to ensure we deliver a premium outcome.

-

REPORT

Following completion, a comprehensive report is provided showing parameters before balancing and the final balancing result.