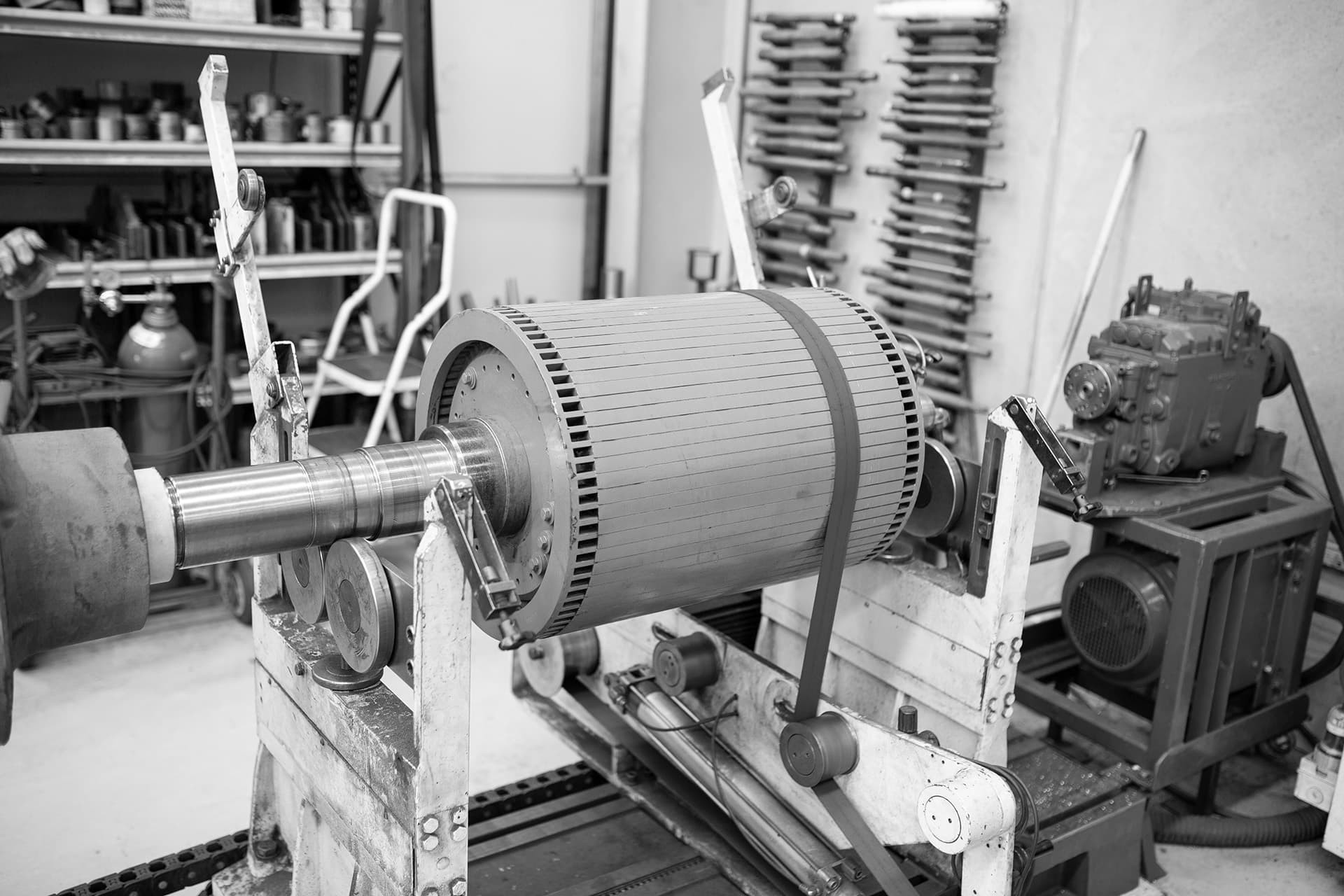

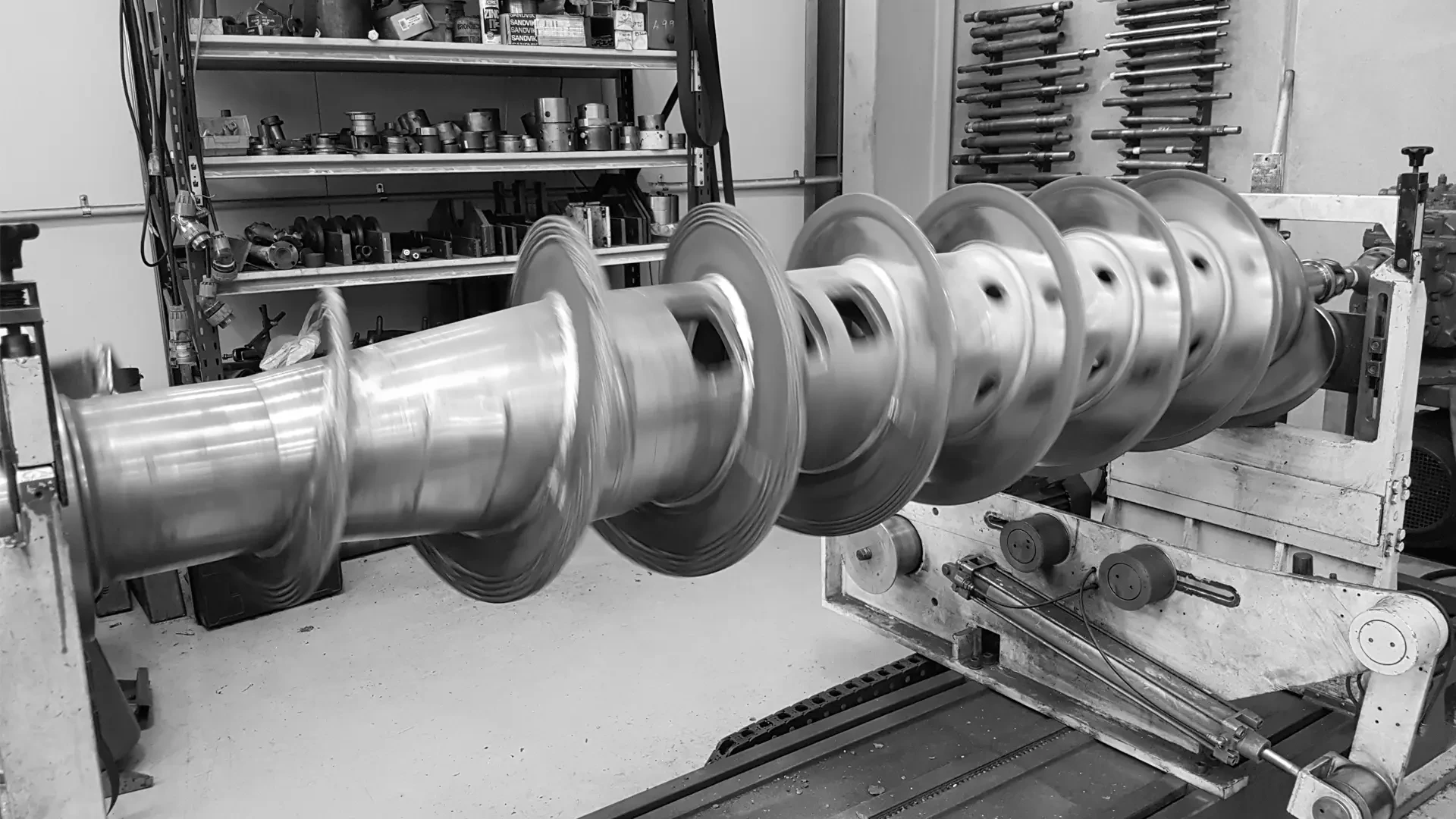

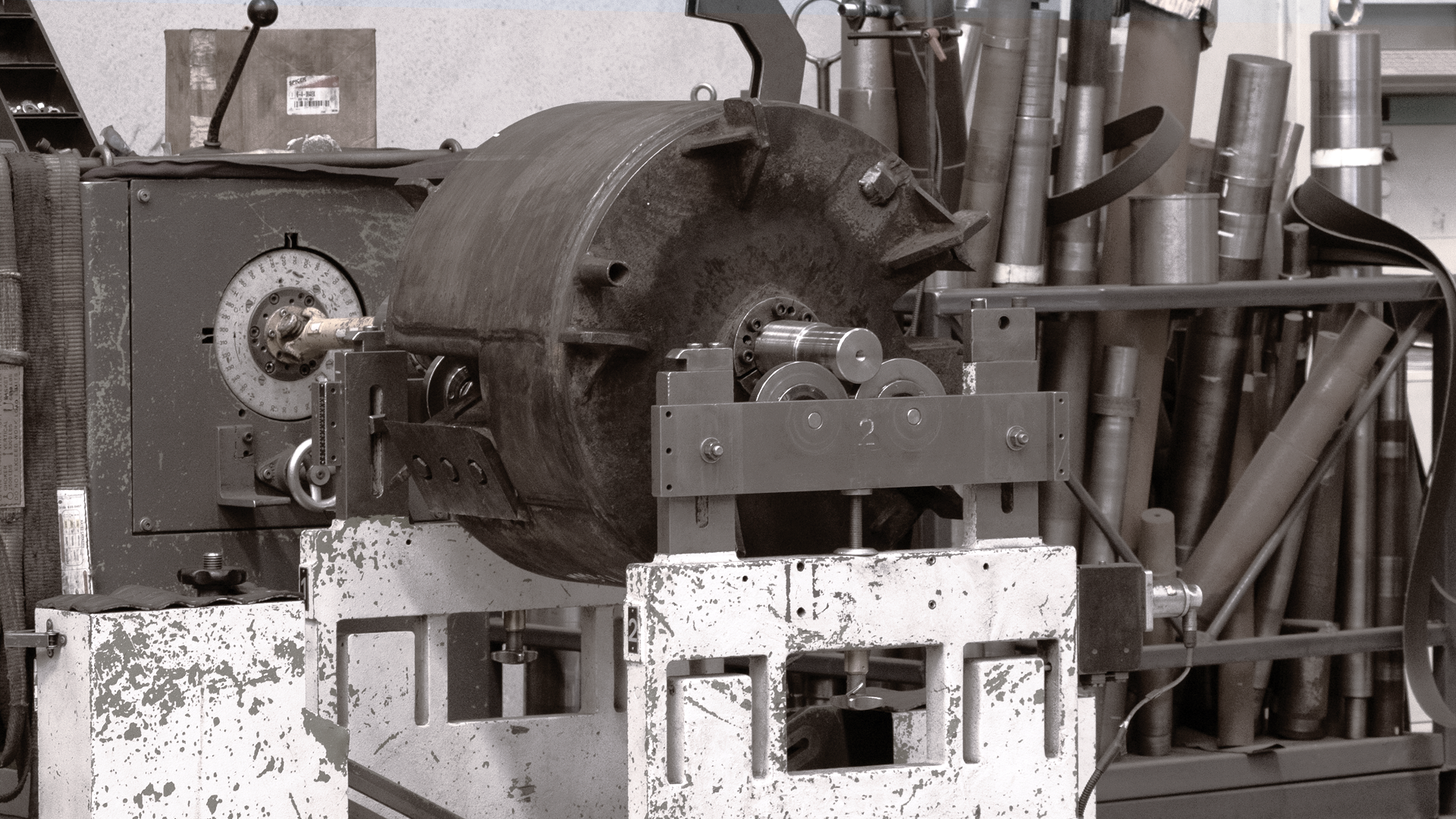

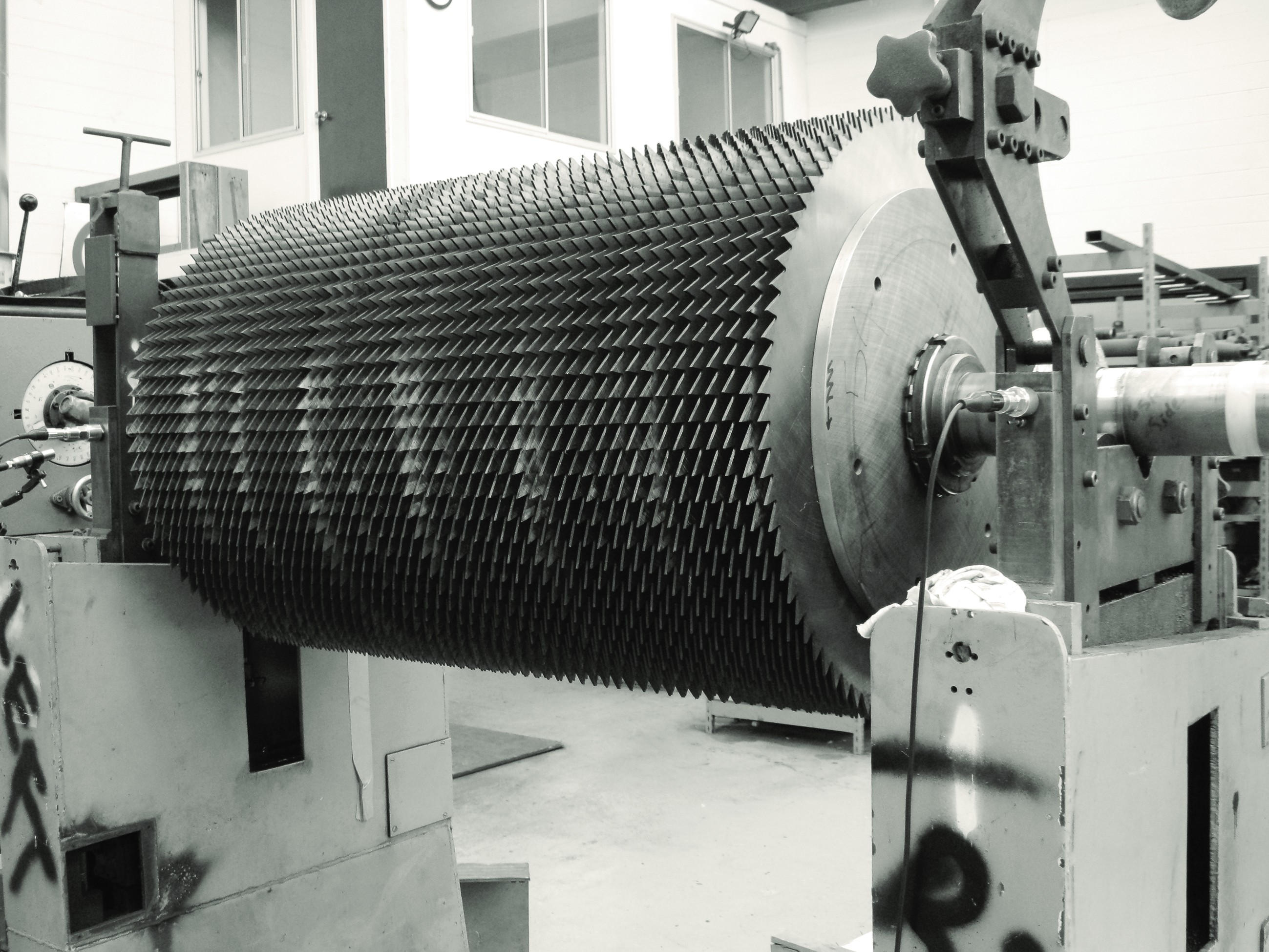

Rotating equipment regardless of its weight, size and application, will have a related industry standard balancing grade to maximise efficiency and protect against premature wear and failure. We also have a wide range of balancing mandrels to suit various applications or can custom manufacture to suit.

- Pulleys

- Bandsaw Wheels

- Crankshafts

- Gears

- Cutter heads

- Compressor screws

- High speed machine tool components

Our Process

-

ASSESS

Beattys will scope the project, identifying any critical parameters and challenges that we need to overcome to ensure we deliver a premium service.

-

ANALYSE

Our balancing technicians will attend the onsite project, complete all compliance procedures and further discuss the issues to ensure we fully comprehend the impact of vibration present.

-

DELIVER

Throughout our Industrial Balancing process, you can be guaranteed of the highest level of engineering and commitment to quality.

-

REVIEW

After dynamic balancing the rotational equipment undergoes a rigorous inspection and quality control measures to ensure we deliver a premium outcome.

-

REPORT

Following completion, a comprehensive report is provided showing parameters before balancing and the final balancing result.