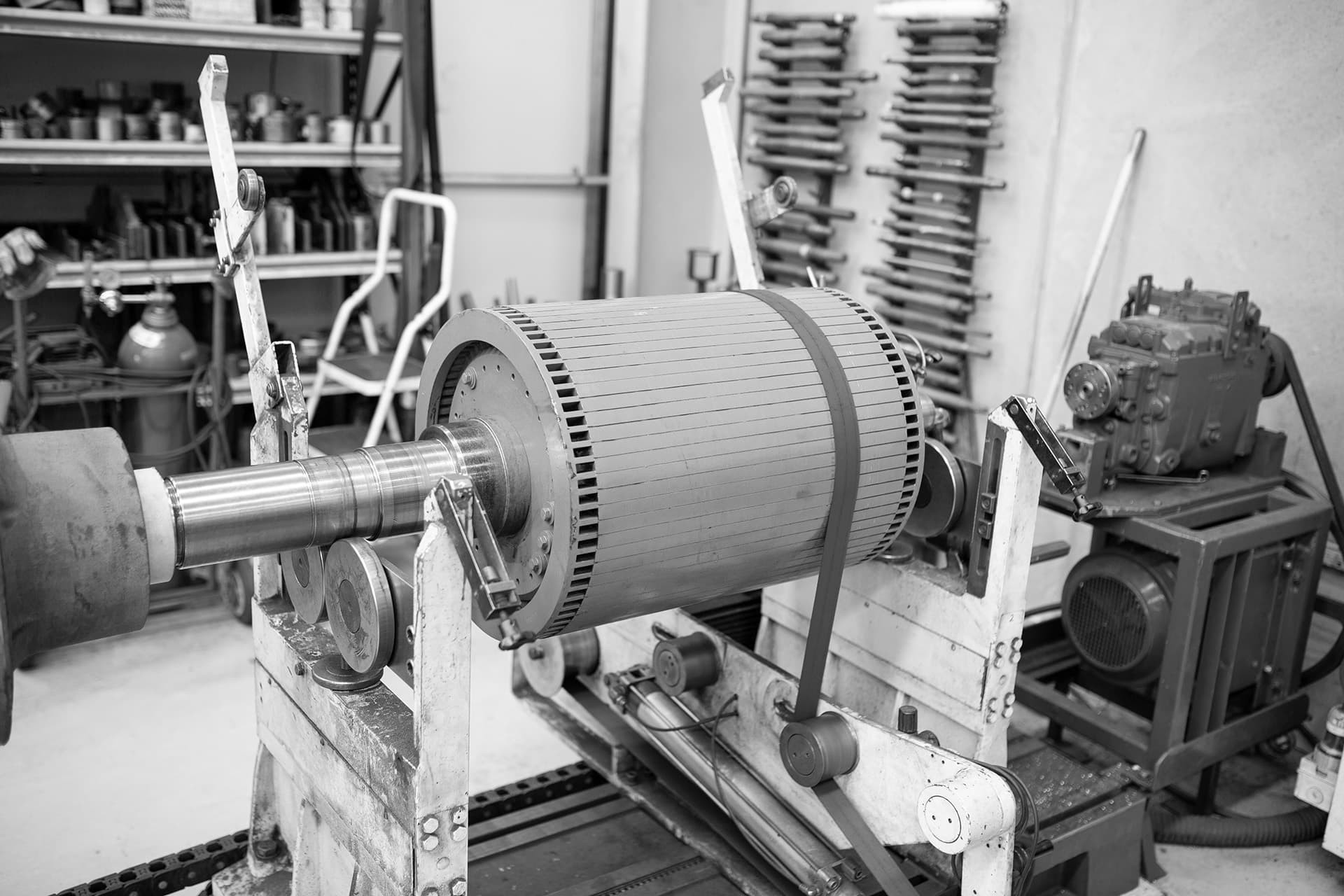

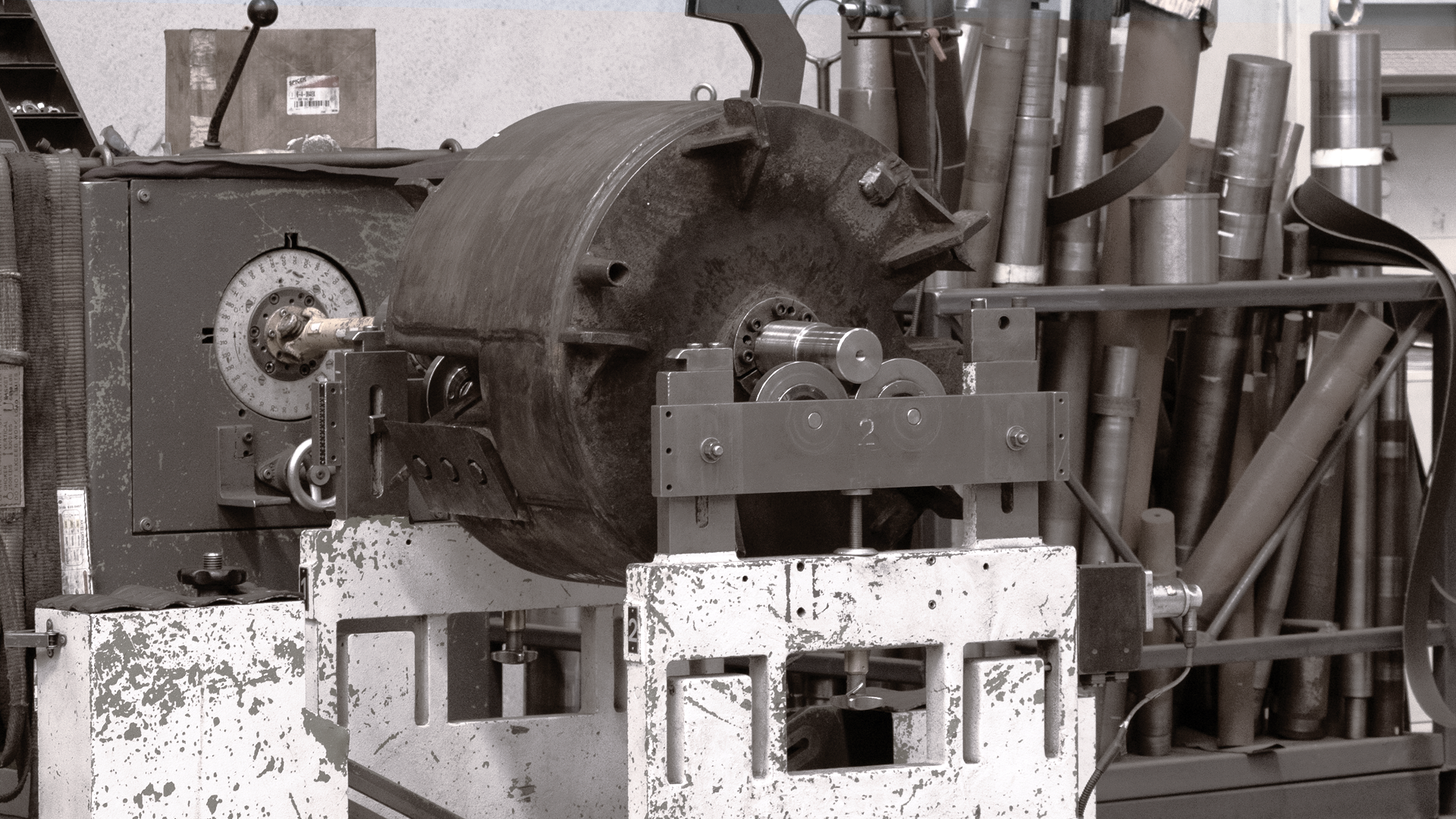

Equipped with our portable dynamic balancer, our technicians are able to visit your site nationwide to diagnose and remedy vibration problems ‘on the spot’, eliminating the need for costly dismantling and freighting of machinery. Difficult access or remote locations no longer present an obstacle to having your componentry dynamically balanced.

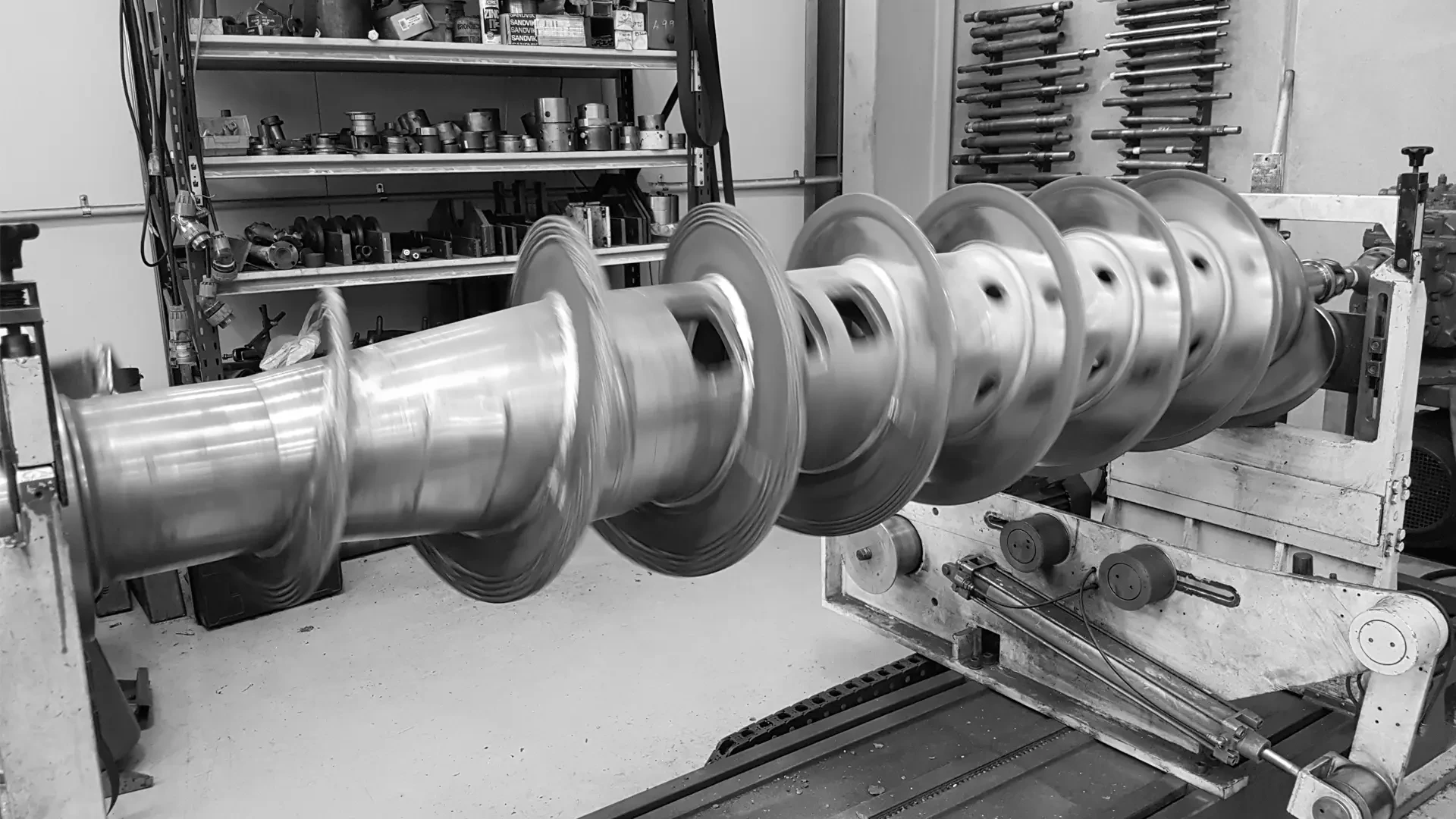

- Air conditioning units

- Cooling tower fans

- Field equipment / machinery

- Air handling units

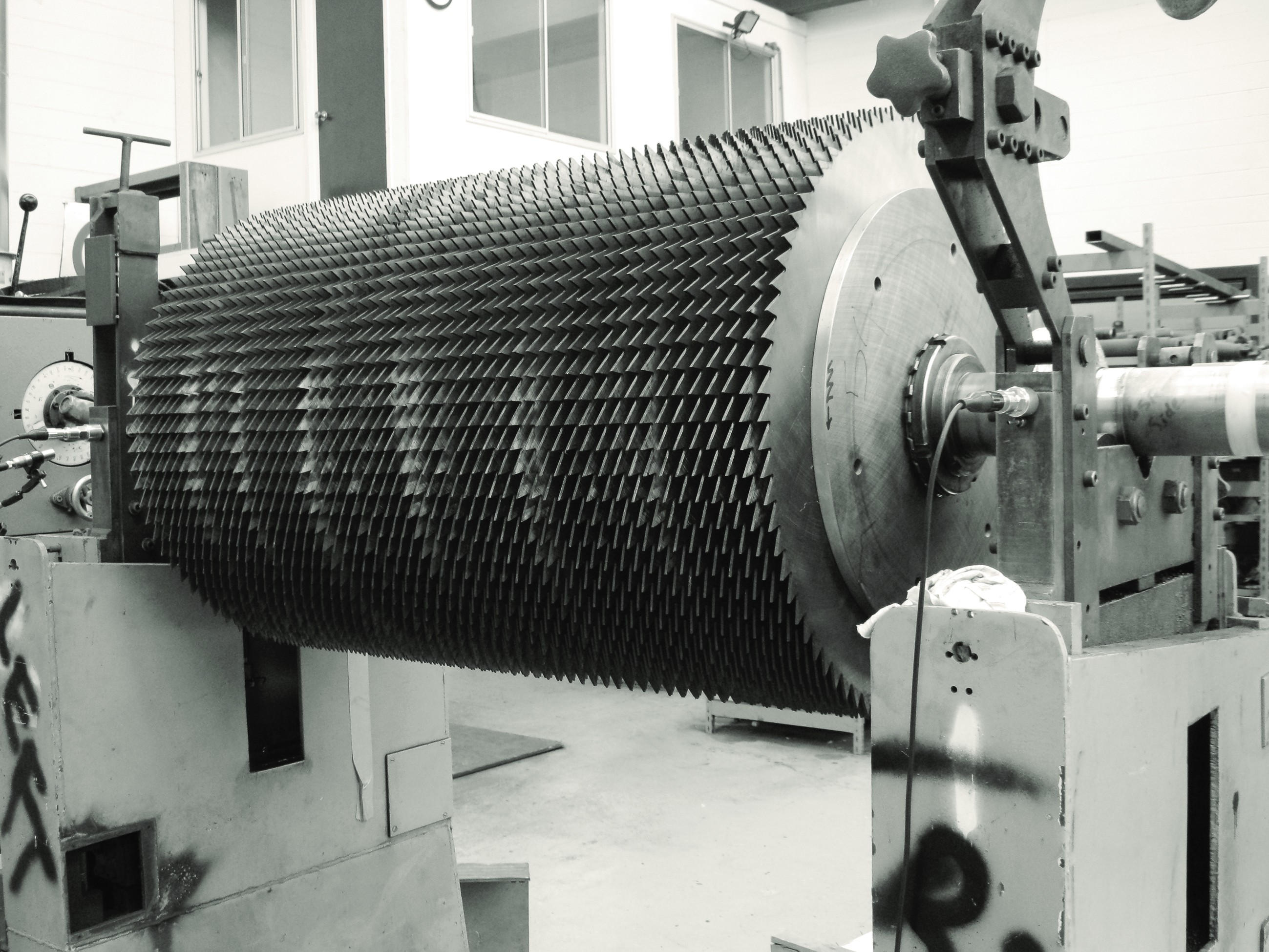

- Bandsaw wheels

Our Process

-

ASSESS

Beattys will scope the project, identifying any critical parameters and challenges that we need to overcome to ensure we deliver a premium service.

-

ANALYSE

Our balancing technicians will attend the onsite project, complete all compliance procedures and further discuss the issues to ensure we fully comprehend the impact of vibration present.

-

DELIVER

Throughout our Industrial Balancing process, you can be guaranteed of the highest level of engineering and commitment to quality.

-

REVIEW

After dynamic balancing the rotational equipment undergoes a rigorous inspection and quality control measures to ensure we deliver a premium outcome.

-

REPORT

Following completion, a comprehensive report is provided showing parameters before balancing and the final balancing result.