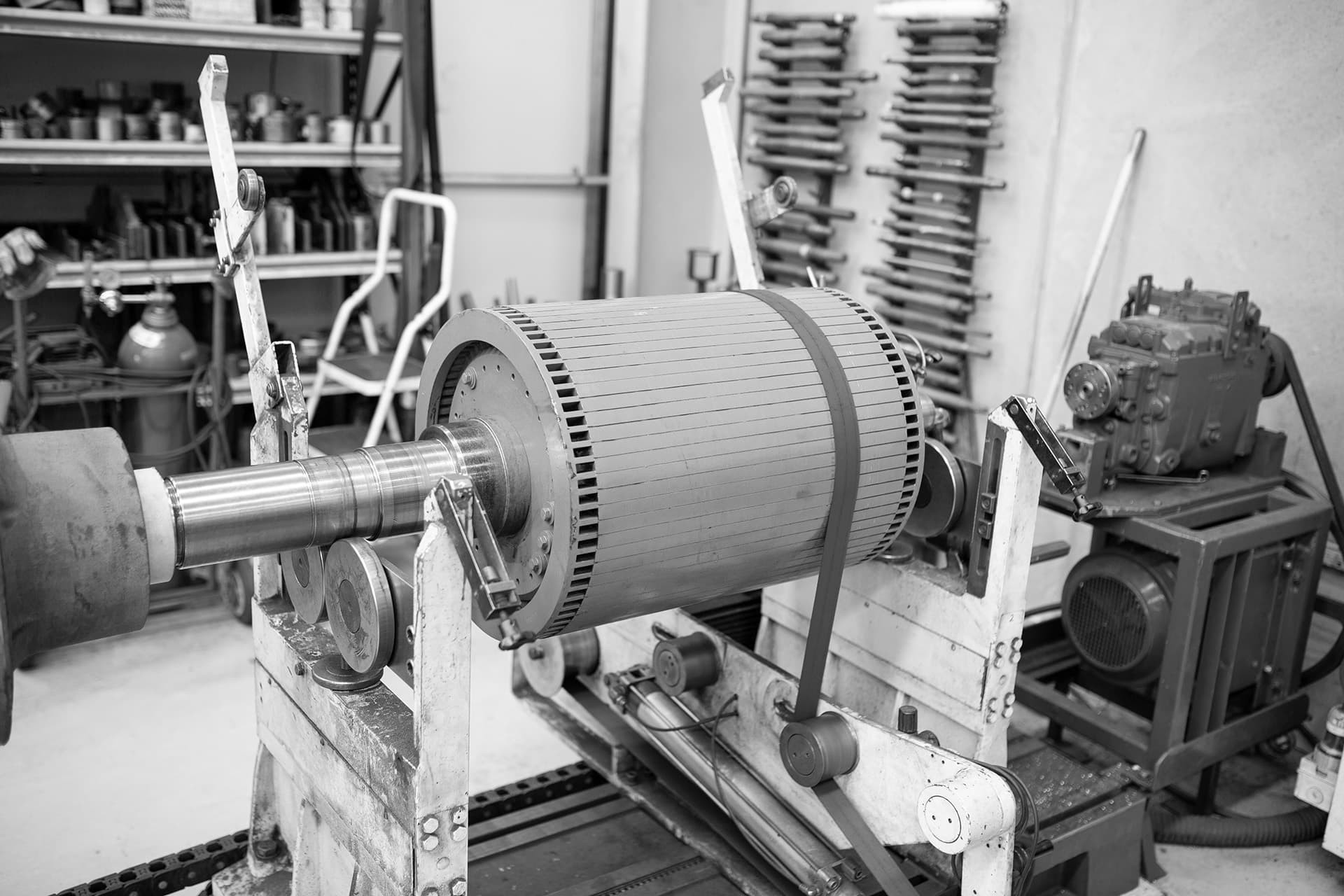

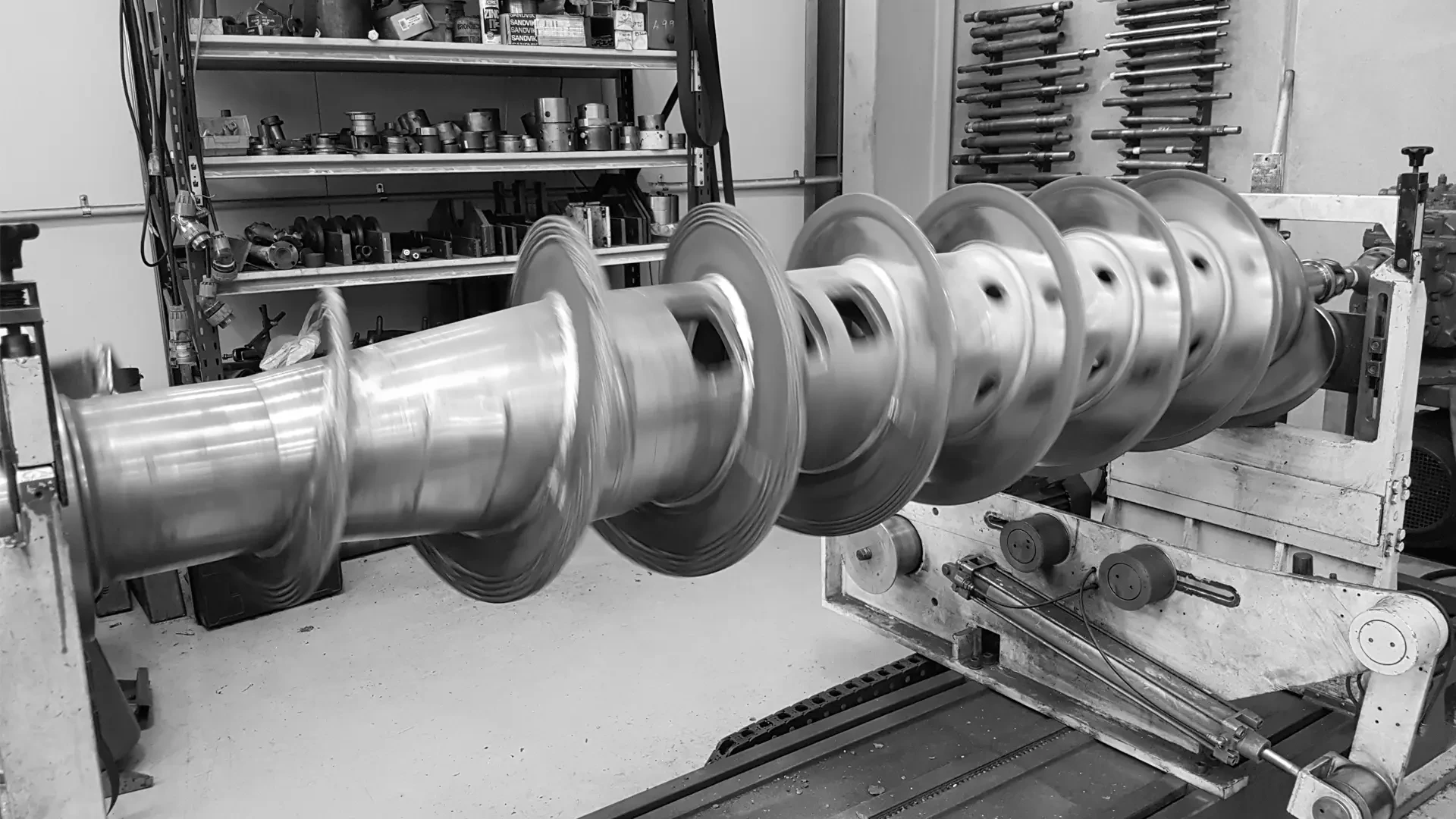

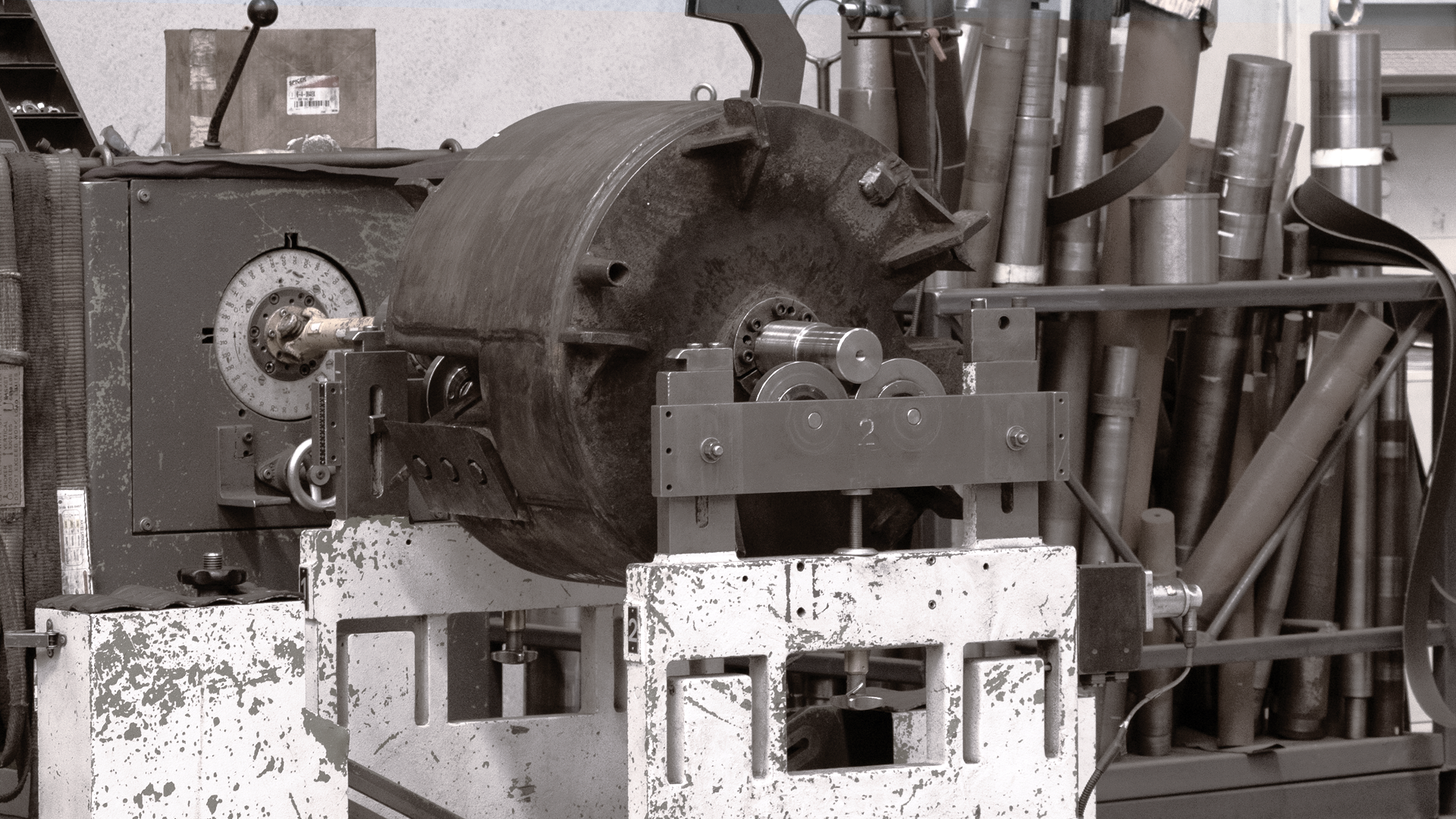

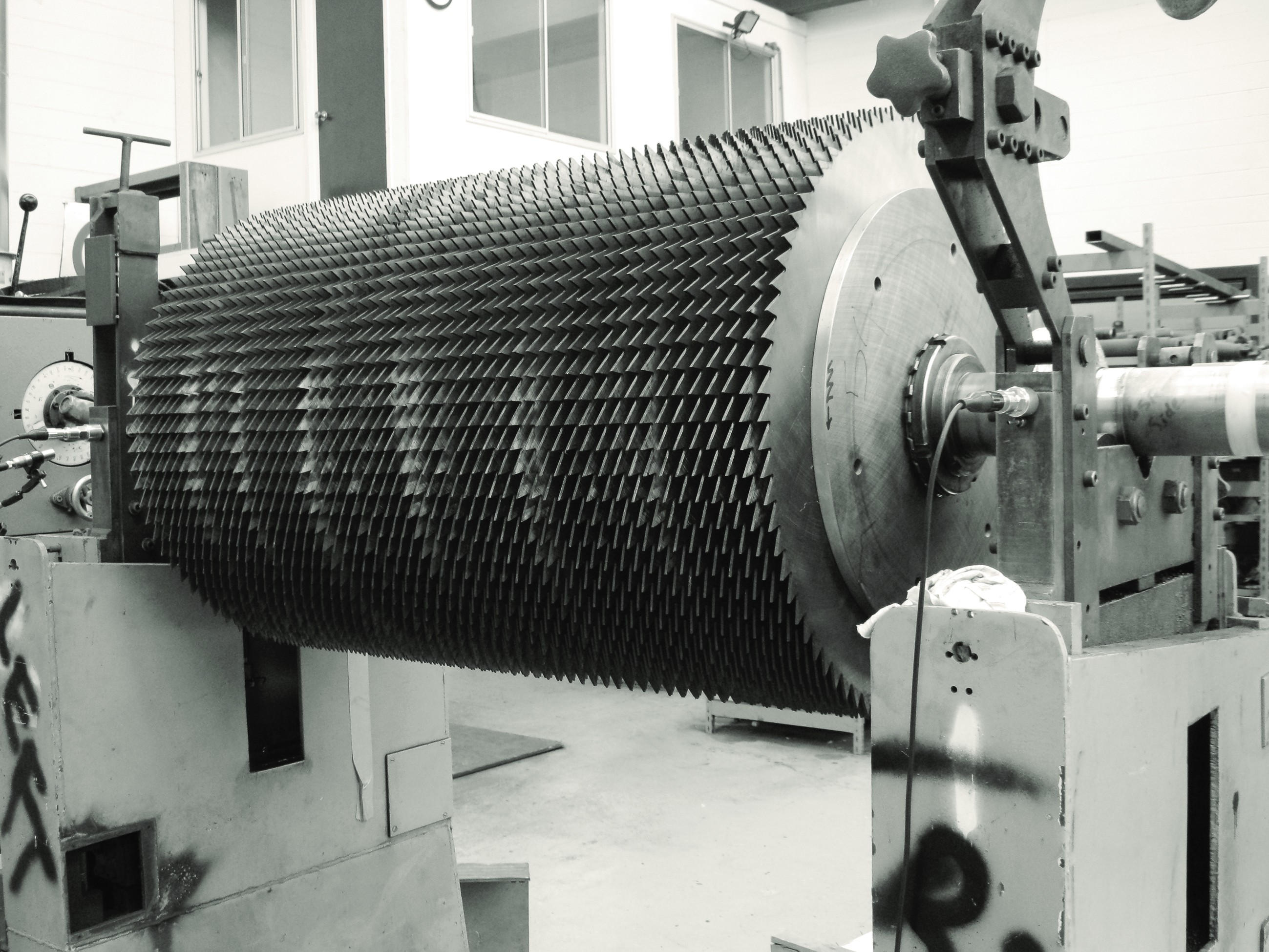

Beattys has a long history of supporting plant reliability through precision dynamic balancing of repaired impellors and armatures during pump rebuilds. Improving balance grades to meet client requirements and ensuring couplings run smoothly are all part of reducing vibration and minimising downtime. Our technicians understand the urgency of getting equipment back online and bring practical experience to a wide range of rotors, from small high-speed aluminium fuel impellors and large generator armatures to multi-stage pump impellors, turbine gear couplings, cast iron waste pumps and bronze industrial process impellors.

- Pump impellers

- Multi-stage pump Impellers

- Fan Impellers

- Armatures

- Electric motors

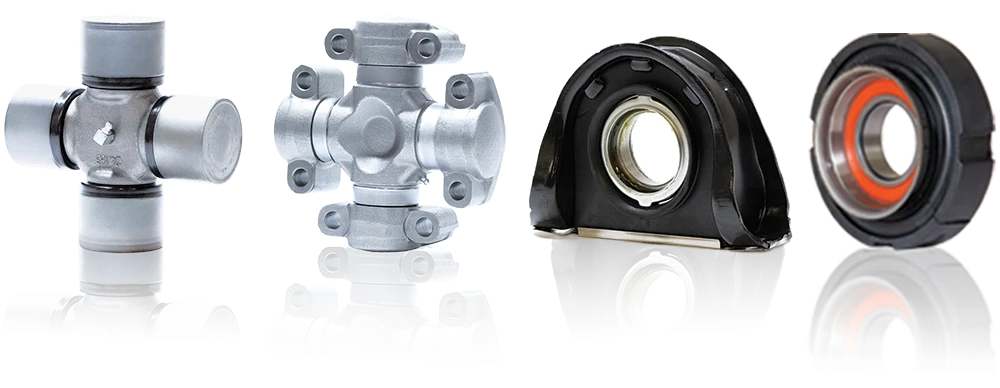

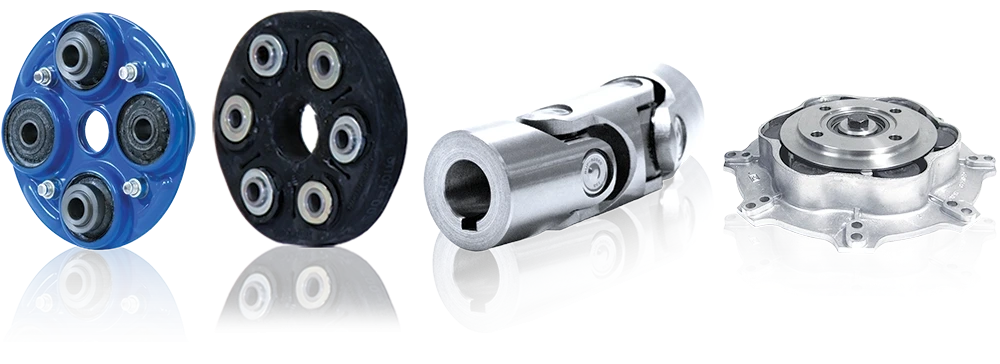

- Couplings

- Pump shafts

Our Process

-

ASSESS

Beattys will scope the project, identifying any critical parameters and challenges that we need to overcome to ensure we deliver a premium service.

-

ANALYSE

Our balancing technicians will attend the onsite project, complete all compliance procedures and further discuss the issues to ensure we fully comprehend the impact of vibration present.

-

DELIVER

Throughout our Industrial Balancing process, you can be guaranteed of the highest level of engineering and commitment to quality.

-

REVIEW

After dynamic balancing the rotational equipment undergoes a rigorous inspection and quality control measures to ensure we deliver a premium outcome.

-

REPORT

Following completion, a comprehensive report is provided showing parameters before balancing and the final balancing result.