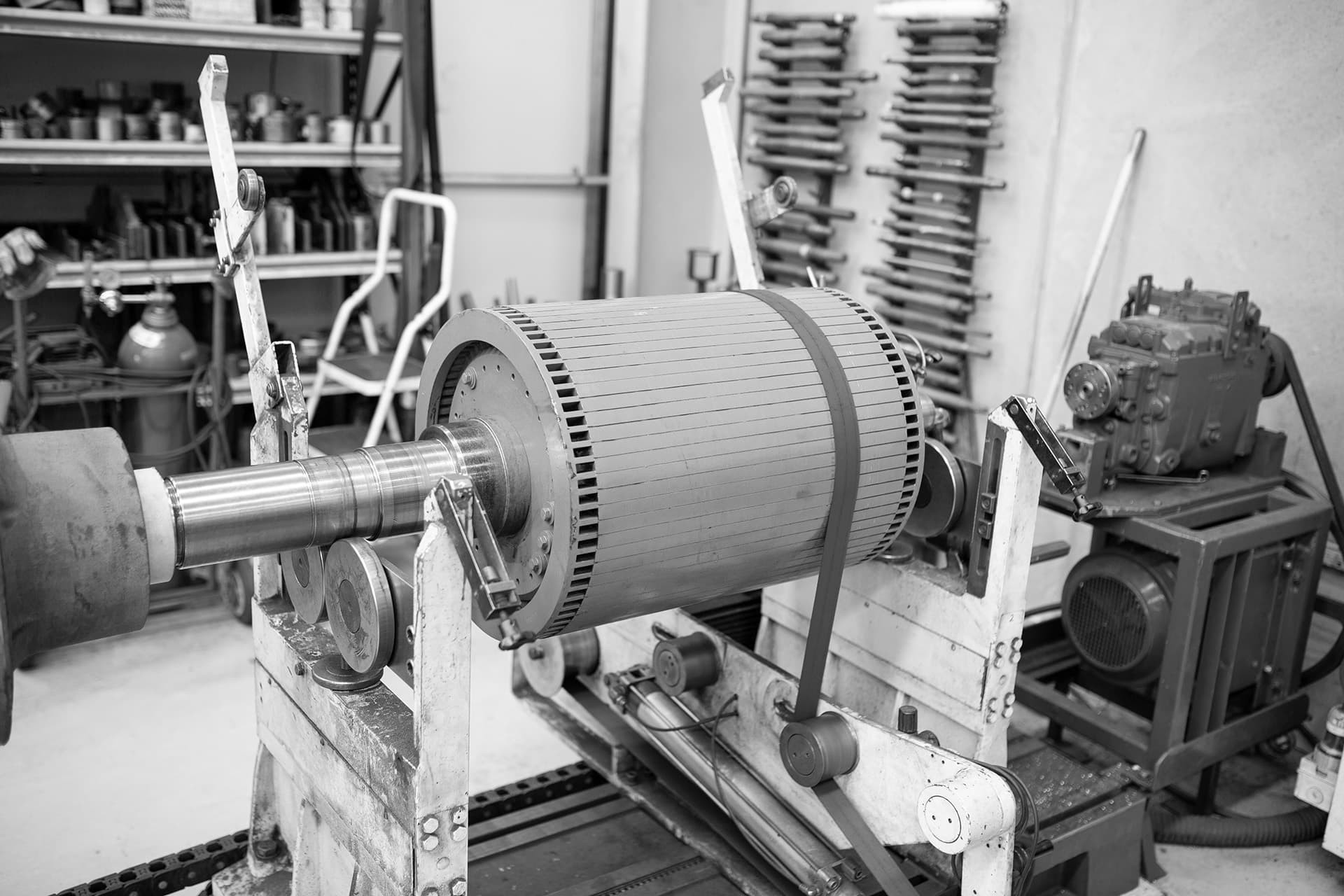

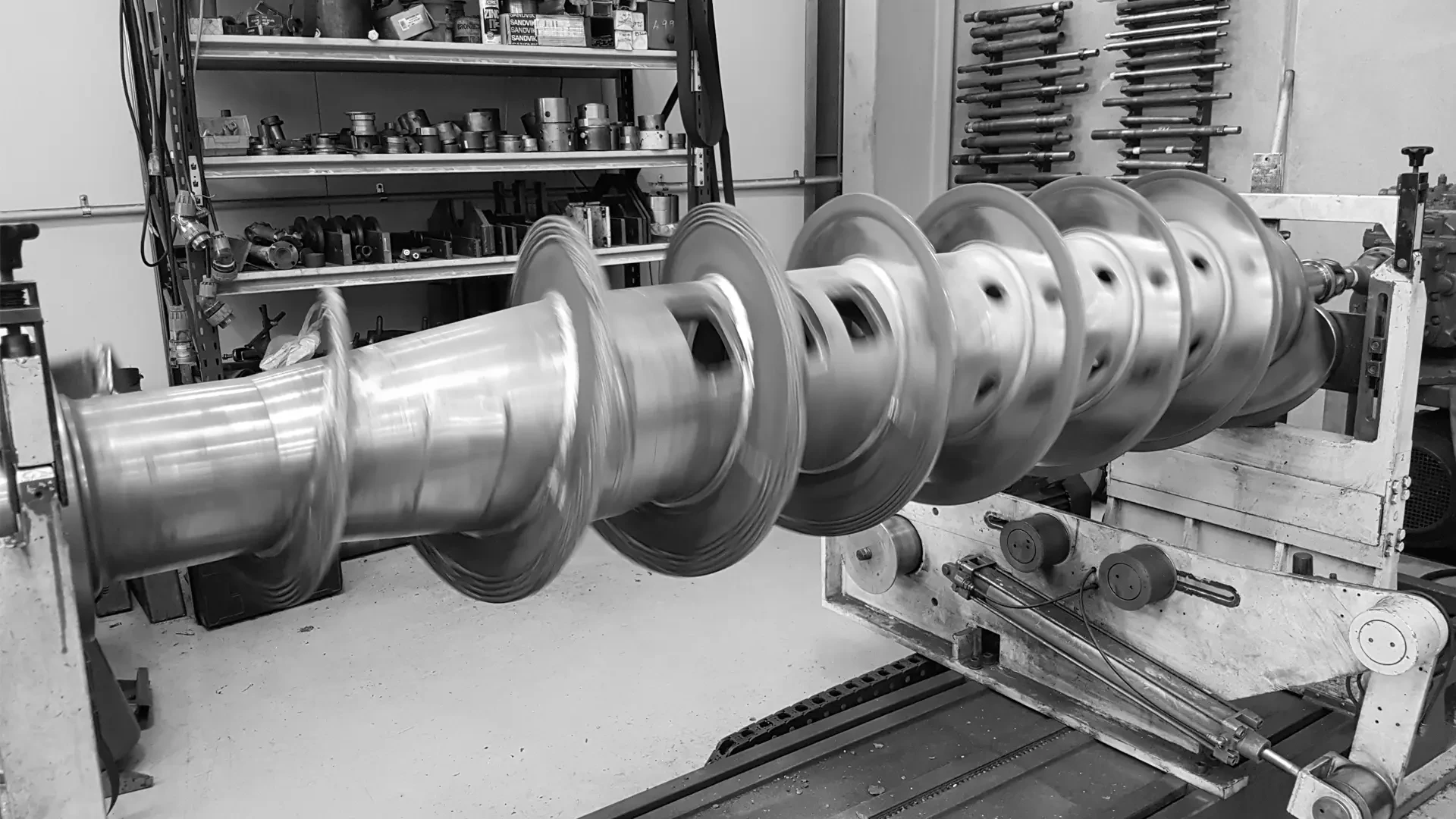

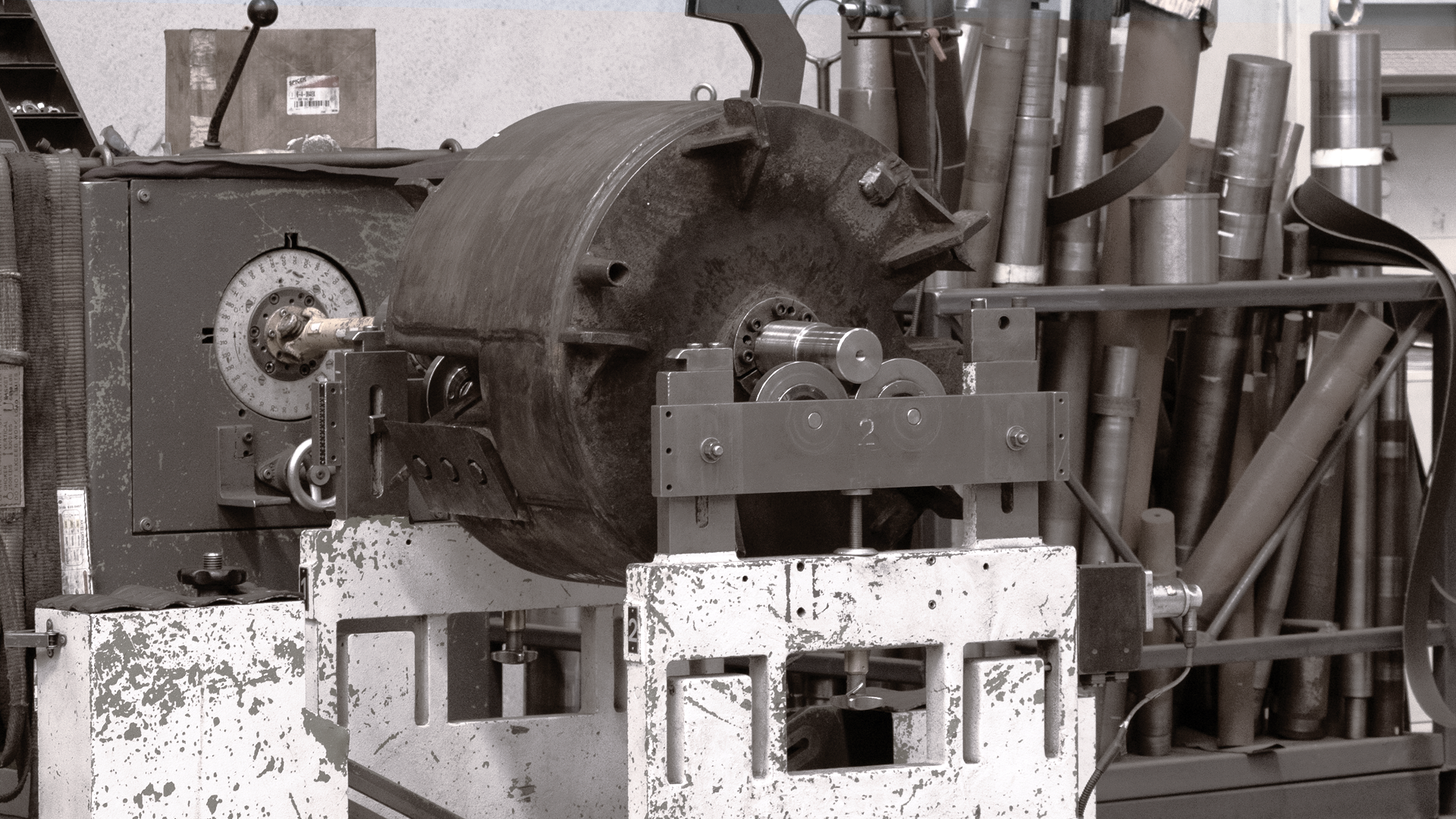

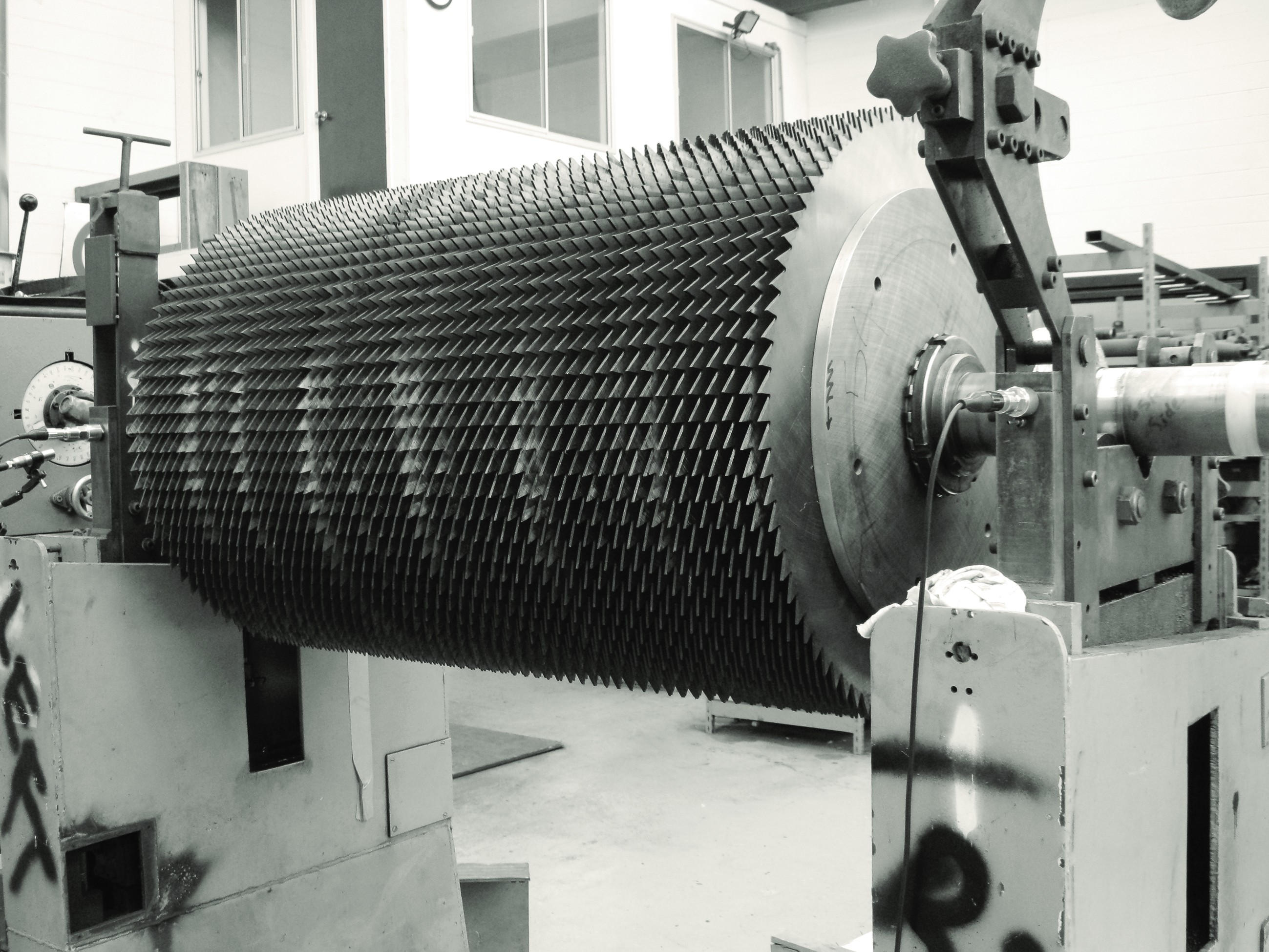

We have the expertise and experience to remove vibration issues from rotors across a broad range of applications. From tree chippers through to high speed agricultural drums, our specialised equipment is capable of balancing all shapes and sizes including rotating components up to 4.5 metres in diameter and 10 tonne in weight.

- Flail drums

- Blades / Chipper discs

- Chipper Drums

- Stump grinding rotors

- Mutching Drums

Our Process

-

ASSESS

Beattys will scope the project, identifying any critical parameters and challenges that we need to overcome to ensure we deliver a premium service.

-

ANALYSE

Our balancing technicians will attend the onsite project, complete all compliance procedures and further discuss the issues to ensure we fully comprehend the impact of vibration present.

-

DELIVER

Throughout our Industrial Balancing process, you can be guaranteed of the highest level of engineering and commitment to quality.

-

REVIEW

After dynamic balancing the rotational equipment undergoes a rigorous inspection and quality control measures to ensure we deliver a premium outcome.

-

REPORT

Following completion, a comprehensive report is provided showing parameters before balancing and the final balancing result.